January began on a cold note with a thick layer of ice forming on the Black Country canals leaving narrowboats stranded and unable to move for several days. Waterfowl, deprived of open water, were rendered vulnerable to predation from foxes. One unfortunate fox that ventured onto the ice in search of a meal drowned when the ice gave way. Nature can be cruel at times!

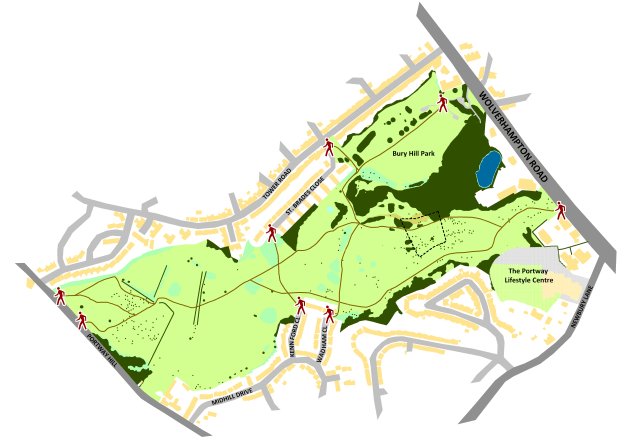

This cold spell was short-lived and relatively mild conditions prevailed for the remaining months of winter. As February drifted into March the daffodils along the roadside on Portway Hill were in full flower and everywhere buds were swelling on trees and shrubs. Spring arrived and with the approach of May the blossoming Hawthorn turned the hillside white.

From then onwards dry weather prevailed. Growth slowed down and by mid-June the grassland had turned yellow. Following the exceptionally wet summer of 2024, this year turned out to be the driest and warmest spring in 50 years, followed by the hottest UK summer on record, with virtually no rain whatsoever.

On the lower eastern slopes of Rowley Hills in Warrens Hall Nature Reserve lives one of the UKs most intriguing true day-flying moths. The Chimney Sweeper Odezia atrata is widely distributed, extending through Western and Central Europe to Britain where it occurs with Pignut, a small, white-flowered member of the carrot family commonly found in grassland, hedgerows, and woodland. The moth eggs are laid in the soil near the food source where they overwinter, and the tiny, green caterpillars hatch the following spring and feed on the flowers and developing seeds. Pupation takes place below the ground surface and the single generation of adults of this unusual sooty black moth with white fringes at the tips of the forewings emerges, flying on bright and sunny days from late-May until late June, occasionally extending into early July. By mid-June the rapidly unfurling fronds of bracken cover the hillside hiding all traces of what has gone before. Is the bracken here beneficial in helping to protect the site, or will it lead to the demise of this caterpillar food plant?

Following the disastrous butterfly year of 2024, with counts of most butterflies and day-flying moths well down on previous years, 2025 saw a recovery, with some species such as Speckled Wood, Gatekeeper, Large White, Small White, and Small Copper doing particularly well. (See Andrew Cook’s butterfly Transect report).

By July the grassland had turning yellow. The tinder dry vegetation led to fires, both on Portway Hill and Warrens Hall Nature Reserve. Grass fires, devastating as they may appear at the time, are also beneficial for wildlife, leaving tracts of bare ground which are rapidly recolonised by plants and animals.

The spring and summer of 2025 provided an opportunity to see how different plants responded to the arid conditions. Many wilted, shrivelled, or just stopped growing. Others appeared unaffected. Both Burnet Saxifrage and Common Toadflax are two such examples, both seen here flowering profusely during August and September. on the south-facing rockface on Portway Hill.

Two led walks took place on Portway Hill this year. In June we welcomed the Bumble Hole volunteers, and in July Halesowen U3A Countryside Studies Group joined us. It goes without saying that both walks took place on hot sunny days.

The discovery of Large Copper Lycaena dispar butterflies along the margin of Swan Pool in Warrens Hall Local Nature Reserve in early August caused great excitement in the butterfly world. Word spread rapidly and saw butterfly photographers flocking to see them from all parts of the country. Extinct in the UK since the middle of the 19th Century because of habitat destruction the butterflies here were believed to be a European subspecies from a country where Large Copper is still quite frequent. Butterflies, eggs and pupal were found confirming breeding had taken place here. Great Water-dock Rumex hydrolapathum, the food plant of the caterpillars, is quite frequent growing around the pool margins and along the nearby canal system. As there is no shortage of the food plant, could this attractive butterfly survive our winter? If so, Large Copper could soon be an established part of the local butterfly community. What we can be sure of is that when August comes around there will be no shortage of butterfly enthusiasts looking for the answer.

Every few years we experience a ‘mast’ year, when trees and shrubs produce an abundance of fruit, nuts, and berries. 2025 was just such a year. Over the years since quarrying and landfill ceased, Portway Hill has become naturally colonised by many different shrubs and trees. These include, Hawthorn, Wild Plum, Blackthorn, Elder, Rowan, Dog Rose, Dogwood, Bird Cherry, Raspberry, Guelder-rose, Ash, Pedunculate Oak, Sycamore, Silver Birch, Whitebeam, and at least eight different species of Cotoneasters. Several different varieties of apple trees are also found here. Where they originate from nobody can be certain. This year, many were laden with fruit, presenting the opportunity to sample apples from different trees. Surprisingly, most tasted much sweeter than shop-bought apples! Another bonus of the mast year was the abundance of blackberries!

The annual meadow cut on the Wildlife Trust owned land on Portway Hill usually takes place in July or August. With this year being so dry, the cut was held back until late September. This delay gave late-summer flowering plants such as Burnet-saxifrage, more time to flower and set-seed. Burnet-saxifrage, a white-flowered member of the Umbellifer family is a relatively uncommon plant on Rowley Hills, reaching its flowering peak in August and September.

When the cut eventually took place the task of collecting the arisings was far less arduous than in previous years.

Autumn arrived, the weather broke, and rain fell. Fungi began to appear, but not in the numbers seen in previous years.

November arrived and a new project began. That of exposing more of the open grassland by removing scrub hawthorn near the Wildlife Trust owned land. This is an ongoing project and will be reported on in 2026.

Nick Horton once again has provided us with a summary of his exciting bird sightings in 2025.If 2024 was a poor year for birds on Rowley Hills, then 2025 was outstanding. The vast amount of insect life due to the work carried out by the Friends of Rowley Hills and the Wildlife Trust plus the long warm sunny summer meant that it was a fantastic year for birds on the Rowley Hills

Plenty of Redwings moved through during January/February and a small flock of Siskins were spotted on Turners Hill in February.

Things kicked off with a bang in March with a male Black Redstart on Portway Hill. Birds spotted on the spring migration included Stonechats, Whinchats, Tree Pipits, Meadow Pipits, Wheatear (one male and one female on Dudley Golf Course, and one male on Bury Hill Park), Ring Ouzel in the horse paddock on Turners Hill and Redstarts near Warrens Hall Riding Stables. A male Pheasant seen on two separate occasions in the paddock to the south of Miles Grove, and Red Kites once again flew over the Portway Hill site until early May.

It was a special year for migrant warblers.

Chiff-chaff – several pairs successfully fledged youngsters.

Blackcap – several pairs successfully fledged youngsters.

Whitethroat- several pairs successfully fledged youngsters.

Lesser Whitethroat- pair noted near to the Wildlife Trust Land on Portway Hill.

Willow Warbler – two pairs on Portway Hill, and one on Turners Hill.

Garden Warbler – a pair nested on the steep slope on Portway Hill behind Wallace Road, and at least three youngsters successfully fledged. (That’s the first since 2012).

An astonishing six species of nesting warblers in an urban area.

And there is encouraging news from Andrew Cook on his Portway Hill Butterfly Transect results.

Portway Hill SINC 01/04/25 – 29/09/25

After the concerning decline in butterfly numbers in 2024 following the cold and wet start to the year, seen country wide, I am pleased to report that butterfly numbers for the 2025 season on Portway Hill are back up to those recorded in previous years.

Thanks to a warm, sunny, though windy start in April, butterfly numbers were significantly up compared to the three previous years I have recorded on The Portway Hill Open Space. A total of 136 butterflies were recorded for the month with good numbers of Orange-tip (45), Speckled Wood (45), Large White (23), Peacock (19), Small White (18) and Green-veined White (11). Also seen, with numbers below 10, were Brimstone, Comma, Green Hairstreak, Holly Blue, Red Admiral, Small Copper and Small Tortoiseshell. This is substantially higher than the same month in 2024, 38 recorded, and double 2023 with 65 recorded, a great start to the year. In total 13 species of butterfly were sighted in April.

May saw an average of 50 sightings per week with the emergence of Small Heath along with the first of the day flying moths being recorded from mid-month. Burnet Companion, in the main, along with Cinnabar, Latticed Heath and a few Mother Shipton were recorded dispersed widely over the hillside. Orange-tip’s were no longer sighted after the second week in May, earlier by a few weeks than previous years, Speckled Wood numbers dropped also during the month, only one was recorded in the later weeks. A total of 20 species were recorded this month, of which 16 were butterflies and 4 were day flying moths.

Numbers began to increase in June, the last two weeks of the month reached 458 and 385 butterflies and moths seen, the peak for the season, which mainly consisted of Ringlet (200 & 223) and Marbled White (154 & 78), all other species, 19 in total, were below 20. Total sightings for June were 1015 recordings.

The beginning of July saw a dip in numbers (181), this was mainly due to a week of cooler, wet and windy weather over the hillside. This probably impacted the numbers of Marbled White and Ringlet observed with numbers declining to zero sightings by the middle of the month, several weeks earlier than normal. With the weather improving during the second week numbers of sightings increased to 414. With increasing numbers of Large & Small White, Meadow Brown and the emergence of Gatekeepers. The first two weeks of July each saw more sightings of Large White, 50 & 58, than the total for 2022 & 2024 and combined 2023. The month ended predominantly with sightings of Gatekeeper and Meadow Brown with decreasing numbers of Large & Small White, along with the emergence of the second brood of Small Heath. July was also a good by comparison for Common Blue, a total of 30 were recorded over the month. 23 species were recorded in July, the peak for the season.

With the beginning of August numbers began to fall, with the exception of slowly declining numbers of Ringlet and Meadow Brown, only steady numbers of Small Heath were recorded, these were in the range of 20 to 30 each week during the month. All other species’ weekly numbers were in single figures except for a brief flurry of a second brood of Speckled Wood early on. Added to this was the emergence of a possible third brood of Small Copper from the middle of the month. 14 species were recorded with a total of 453 sightings over the month.

September, as usual, saw a decline in the number of sightings to single figures of each of the 9 species recorded. The exception to this was the Small Copper, the number of which peaked in the first week at 14, the most I had recorded in one day and, except for 2023, more than the total in previous years. 51 sightings were recorded during September.

| SPECIES | 2022 | 2023 | 2024 | 2025 |

| Ringlet | 589 | 413 | 641 | 515 |

| Meadow Brown | 563 | 596 | 459 | 281 |

| Gatekeeper | 443 | 468 | 349 | 527 |

| Marbled White | 353 | 464 | 145 | 291 |

| Small Heath | 179 | 201 | 111 | 192 |

| Burnet Companion | 159 | 54 | 53 | 37 |

| Small Tortoiseshell | 52 | 86 | 45 | 48 |

| Large White | 50 | 109 | 36 | 220 |

| Latticed Heath | 39 | 45 | 15 | 23 |

| Small White | 38 | 70 | 41 | 108 |

| Large Skipper | 36 | 30 | 10 | 37 |

| Common Blue | 35 | 65 | 20 | 70 |

| Peacock | 29 | 78 | 32 | 35 |

| Speckled Wood | 24 | 52 | 54 | 77 |

| Comma | 20 | 45 | 9 | 22 |

| Small Skipper | 19 | 126 | 64 | 42 |

| Green-veined White | 16 | 29 | 10 | 29 |

| Small Copper | 13 | 16 | 2 | 38 |

| Holly Blue | 12 | 5 | 3 | 4 |

| Essex Skipper | 11 | 47 | 29 | 6 |

| Red Admiral | 11 | 51 | 11 | 24 |

| Six-Spot Burnet | 11 | 18 | 14 | 15 |

| Narrow-B’d 5-spot Burnet | 10 | 6 | 5 | 22 |

| Green Hairstreak | 5 | 6 | 0 | 5 |

| Painted Lady | 5 | 1 | 0 | 11 |

| Shaded Broad-bar | 4 | 20 | 6 | 2 |

| Brimstone | 3 | 6 | 4 | 2 |

| Orange-tip | 3 | 42 | 16 | 45 |

| Cinnabar | 3 | 0 | 0 | 7 |

| Mother Shipton | 2 | 1 | 0 | 2 |

| Hummingbird Hawk Moth | 1 | 1 | 0 | 2 |

| Silver Y | 0 | 4 | 10 | 1 |

| Total For Year | 2738 | 3155 | 2194 | 2740 |

| Species For Year | 33 | 36 | 31 | 32 |

| Weeks Transect Missed* | 5 | 1 | 1 | 4 |

| *Due to Availability/Weather |

As the end of the year approached preparations were made once again to see in the New Year, with volunteers and friends gathered at the top of Portway Hill at the stroke of midnight to watch the display of fireworks.

What does 2026 has in store for us. Will it be a repeat of 2025 with another dry summer, or will it turn out to be a wet year like 2024? We shall see.